Hope Valley Railway Upgrade

Network Rail

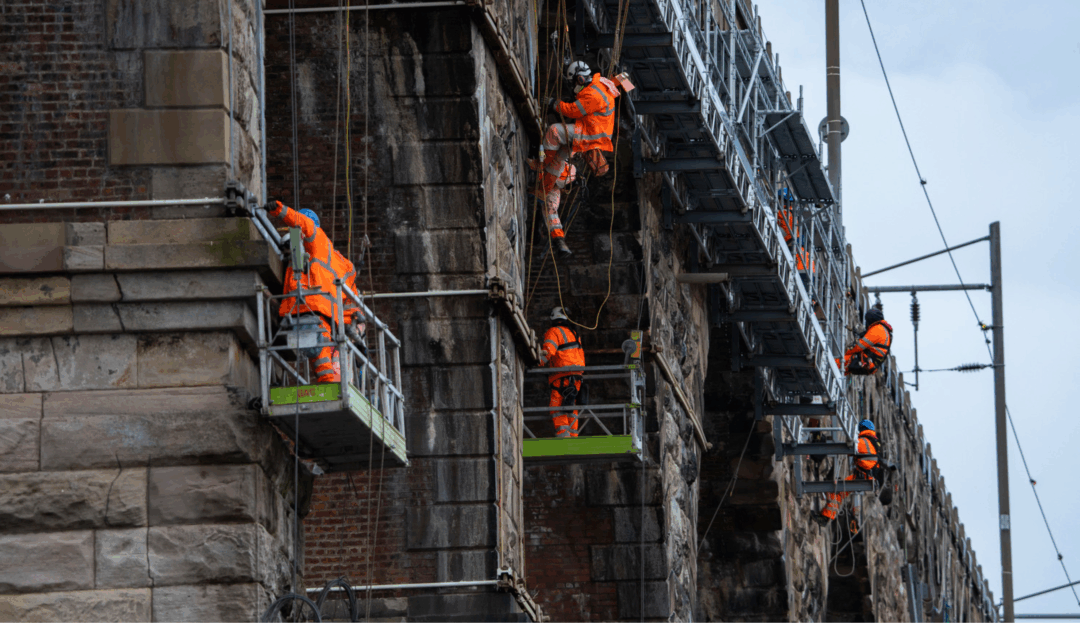

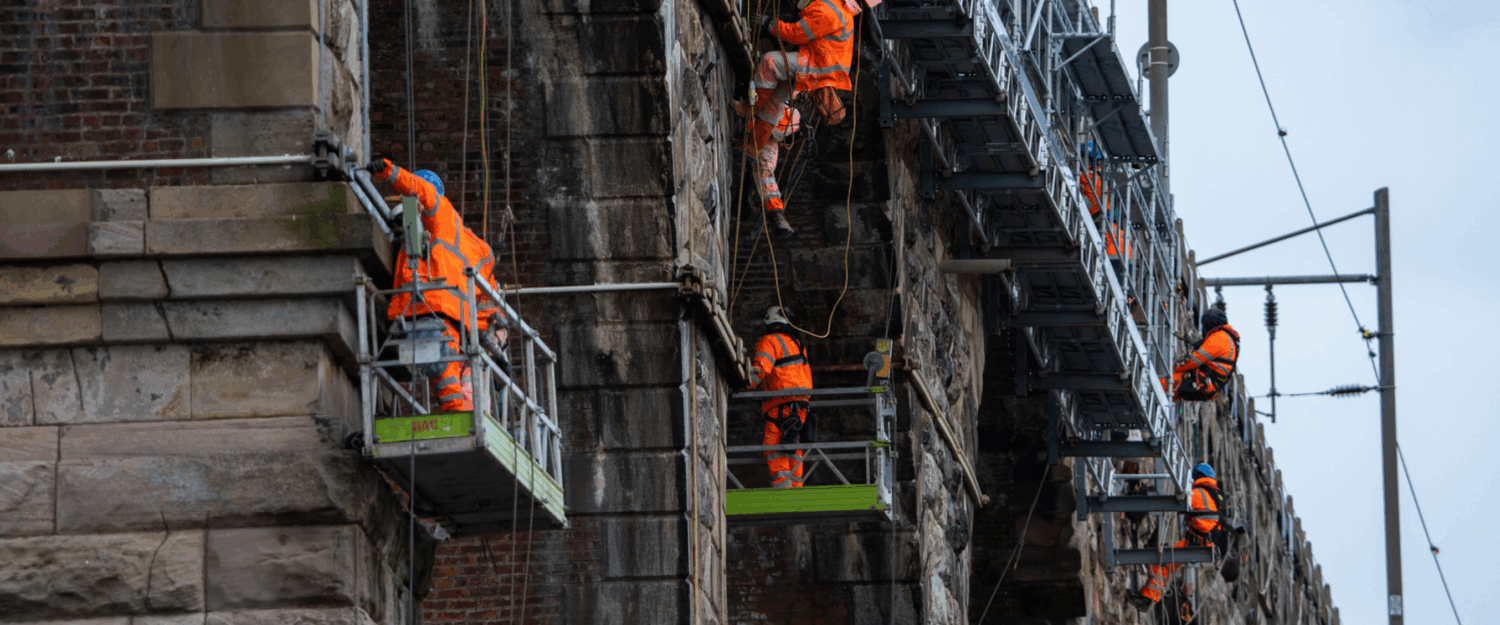

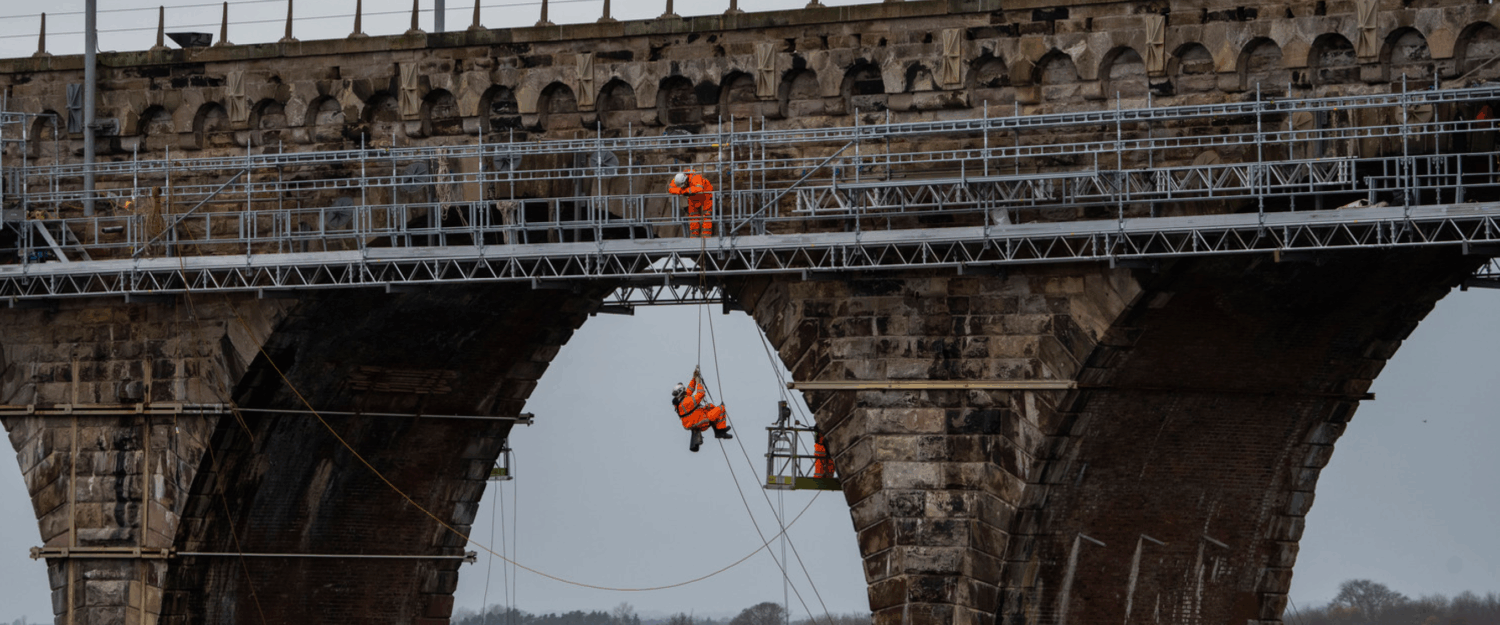

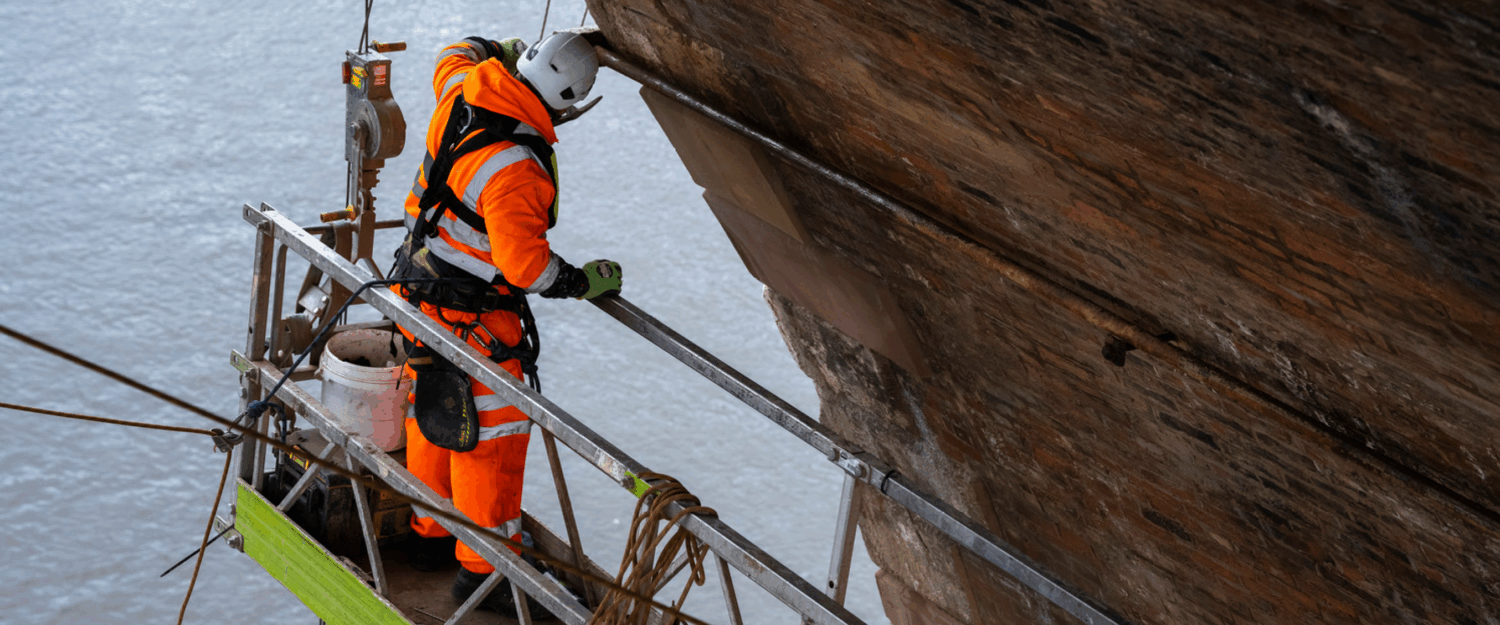

VolkerRail/Story joint venture were tasked with the £80m project as part of a £137m investment that saw the undertaking of extensive enhancement works to remove several bottlenecks along the route to improve reliability, increase passenger services and aid in freight movements.